Three Mile Island Documentary

The Three Mile Island accident was a partial nuclear meltdown that occurred on March 28, 1979, in one of the two Three Mile Island nuclear reactors in Dauphin County, Pennsylvania, United States. It was the worst accident in U.S. commercial nuclear power plant history.The incident was rated a five on the seven-point International Nuclear Event Scale: Accident With Wider Consequences.

Three Mile Island Pennsylvania Nuclear Power Station Meltdown - Top Documentary Films-0

Three Mile Island Pennsylvania Nuclear Power Station Meltdown - Top Documentary Films.

MELTDOWN AT THREE MILE ISLAND-0

Documentary Of 1979 Three Mile Island Nuclear Accident.

Overview[]

Three Mile Island Nuclear Generating Station (commonly abbreviated as TMI) is a closed nuclear power plant on Three Mile Island in Londonderry Township, Dauphin County, Pennsylvania on Lake Frederic, a reservoir in the Susquehanna River just south of Harrisburg. It has two separate units, TMI-1 (owned by Constellation Energy) and TMI-2 (owned by EnergySolutions).

The location[]

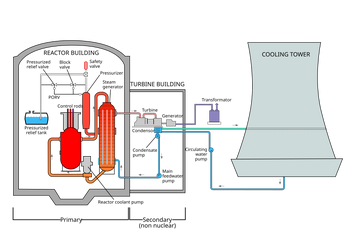

Simple Schematic of the Three Mile Island Nuclear Generating Station Unit 2 Nuclear Power Plant.

The Three Mile Island accident was a major partial nuclear meltdown event that occurred on March 28, 1979, in 1 of the 2 Three Mile Island power plant's nuclear reactors, in Dauphin County, Pennsylvania. It was the worst accident in U.S. commercial nuclear power plant history to date and the 3rd worst case in the world, with Chernobyl and Fukajima being worse.

The atomic power station was built in 1974 on a large river sandbar on Pennsylvania’s Susquehanna River, just 10 miles downstream from the state capitol of Harrisburg. The state-of-the-art Reactor 2 was made in 1978, as a hoped for way of generating affordable and reliable energy in the 1970s energy crises caused by trouble in the Middle East.

Light bulbs[]

The technical design of the PORV indicator light and/or it's instillation were fundamentally flawed. The bulb was simply connected in parallel with the relief valve solenoid, thus implying that the PORV was shut when it went dark, without actually verifying the real position of the valve.

When everything was operating correctly, the indication was true and the operators became habituated to rely on it with out considering it may have been lying to them!

Unfortunately, when things went wrong and the main relief valve stuck open, the unlit lamp was actually misleading the operators by implying that the valve was shut, thus making the Three Mile Island accident a lot worse than it could have been if they had acted sooner.

The operators were not appropriately trained and did understand the ambiguous nature of the PORV indicator. Because of this, they did not look for alternative confirmation that the main relief valve was in fact closed.

An episode of the TV show Mayday, also known as Air Crash Investigation(s) also featured an aircraft, whose accident scenario became a lot worse after the crew became obsessed with a defective light bulb on the control panel.

The lead up to the accident[]

President Jimmy Carter leaving Three Mile Island for Middletown, Dauphin County, Pennsylvania, April 1, 1979.

Pre-SCRAM events[]

It was a civil partial nuclear meltdown that poisoned a large area of Pennsylvania, including a major city. The cause was human errors and mechanical problems with a stuck valve that controlled steam flows.

That night TMI-2 reactor was running at 97% of full power, while the companion TMI-1 reactor was shut down for refuelling. It all began at 4:37 am EST, on March 28, 1979, in TMI-2's secondary loop, one of the three main water/steam loops in a pressurized water reactor (PWR).

An attempt by operators to fix a blockage in one of the 8 condensate polishers, the high tech filters cleaning the secondary loop water, 11 hours earlier jammed the valve. Blockages are common with these sophisticated resin filters and are usually fixed easily, but in this case the usual method of forcing the stuck resin out with compressed air did not succeed.

With the steam generators no longer receiving feedwater, the reactor became very hot and hyperactive. As heat and pressure increased in the reactor coolant system the reactor automatically perform a 'SCRAM' emergency shutdown and within 8 seconds, the control rods were inserted into the core to halt the nuclear chain reaction.

Post-SCRAM events[]

The hyper-hot/active reactor overwhelmed the (most likely boron or graphite) control rods and continued to generate decay heat. Since steam was no longer being used by the generating turbine, heat was no longer being removed from the reactor's primary water loop. Once the secondary feedwater pumps stopped, 3 auxiliary pumps activated automatically, but because the valves had been closed for routine maintenance in violation of a key NRC rule, so the system was unable to pump any water. The NRC rules stated the reactor must be shut down if all auxiliary feed pumps are closed for maintenance. This was later singled out by angry NRC officials as a key failure.

This triggered the pilot-operated relief valve (PORV) at the top of the pressuriser – a pressure active-regulator tank – to open automatically. It should have closed when the excess pressure had been released, and electric power to the solenoid of the pilot was automatically cut, but the open valve permitted coolant water to escape from the primary system and was the principal mechanical cause of the partial meltdown that followed.

Human factors: Confusion over valve status and the status of the solenoid by the operators meant did not correctly diagnose the problem for several hours.

The PORV indicator light's unlit lamp mislead the operators in to behaving the valve was shut. This caused the operators considerable confusion, because the pressure, temperature and coolant levels in the primary circuit, were apparently not behaving as they would have if the PORV were shut.

This confusion meant the staff were unable to break out of a cycle of assumptions that conflicted with what their instruments were telling them. The operators were not appropriately trained and did understand the ambiguous nature of the PORV indicator. Because of this, they did not look for alternative confirmation that the main relief valve was in fact closed.

Events after the new shift arrived[]

It was not until a fresh shift came in, who did not have the mind-set of the first shift of operators, that the problem was correctly diagnosed. By this time major damage had occurred thanks to the earlier shift's poor training, dithering, bad habits, inflexibility, confusion and incompetence.

There was a temperature indicator downstream of the PORV in the tail pipe between the PORV and the pressurizer that could have told them the valve was stuck open, by showing that the temperature in the tail pipe remained higher than it should have been had the PORV been shut. This temperature indicator, however, was not part of the "safety grade" suite of indicators designed to be used after an incident, and the operators had not been trained to use it. Its location on the back of the desk also meant that it was effectively out of sight of the operators.

The consequences of stuck valve[]

As the pressure in the primary system continued to decrease, reactor coolant, which was boiling inside the core, continued to flows. At first, small bubbles of steam, known as nucleate boiling, formed and immediately collapsed.As the pressure decreased further, steam pockets then began to form in the reactor coolant. This departure from nucleate boiling (DNB) into the regime of "film boiling" caused steam voids in coolant channels, thus blocking the flow of liquid coolant and greatly increasing the fuel cladding temperature.

Because of the lack of a dedicated instrument to measure the level of water in the core, operators judged the rapidly rising level of water in the reactor core solely by the level in the pressuriser, thus leading to a fatal error occuring in there readings.

Since the pressure was apparently high, they wrongly assumed that the core was properly covered with coolant, not knowing it was mostly steam forming in the reactor vessel, the indicator provided misleading readings. Indications of high water levels contributed to the confusion, as operators were concerned about the primary loop "going solid," (i.e. having no steam pocket buffer existing in the pressuriser) which in training they had been instructed to never allow! This confusion was a key contributor to the initial failure to recognise the accident as a loss-of-coolant accident, and led operators to turn off the emergency core cooling pumps, which had automatically started after the PORV stuck and core coolant loss began, due to fears the system was being overfilled. Panick had broke out at this point.

With the PORV still open, the pressurizer relief tank that collected the discharge from the PORV overfilled, causing the containment building sump to fill and sound an alarm at 4:11 am. This alarm, along with higher than normal temperatures on the PORV discharge line and unusually high containment building temperatures and pressures, made it clear they were having a loss-of-coolant accident, but it was initially ignored by operators.

At 4:15 am, the relief diaphragm of the pressurizer relief tank ruptured leadng to radioactive coolant leaking into the general containment building. The radioactive coolant was pumped from the containment building sump to an auxiliary building, outside the main containment, until the sump pumps were stopped at 4:39 am.

In 1 hour and 20 minuets, the slow temperature rise finaly the primary loop's four main reactor coolant pumps cavitate as a steam bubble/water mixture, rather than water, passed through them. As a result pumps were shut down it was believed that natural circulation would continue the water movement, but the steam in the system prevented flow through the core, and as the water stopped circulating it was converted to steam in increasing amounts.

About 2hours and 10 minutes after the first malfunction had occered , the top of the reactor core was exposed and the intense heat caused a reaction to occur between the steam forming in the reactor core and the Zircaloy nuclear fuel rod cladding, yielding zirconium dioxide, hydrogen, and additional heat. This reaction melted the nuclear fuel rod cladding and damaged the fuel pellets, which released radioactive isotopes to the reactor coolant, and produced hydrogen gas that is believed to have caused a small explosion in the containment building later that afternoon. At 6 am, there was a shift change in the control room. A new arrival noticed that the temperature in the PORV tail pipe and the holding tanks was excessive and used a backup valve – called a "block valve" – to shut off the coolant venting via the PORV, but around 32,000 US gal (120,000 l) of coolant had already leaked from the primary loop. It was not until 165 minutes after the start of the problem that radiation alarms activated as contaminated water reached detectors; by that time, the radiation levels in the primary coolant water were around 300 times expected levels, and the plant was seriously contaminated.

The accident occurs[]

Emergency declared[]

Release of radioactive material[]

Later events[]

The evacuation[]

The state's governor, Governor Dick Thornburgh, had on the advice of NRC chairman Joseph Hendrie, advised the evacuation "of pregnant women and pre-school age children...within a five-mile radius of the Three Mile Island facility." The evacuation zone was extended to a 20-mile radius on Friday March 30. Within days, 140,000 people had left the area. More than half of the 663,500 population within the 20-mile radius remained in that area. According to a survey conducted in April 1979, 98% of the evacuees had returned to their homes within three weeks. Later, the Pennsylvania House of Representatives conducted an investigation, which focused on the need to improve evacuation procedures. About 50% of the population then and still support the idea of the evacuation.

The cleanup begins[]

Aftermath[]

At the accident site[]

The cleanup started in the August of 1979, and officially ended in the December of 1993, with a total cleanup cost of about $1 billion. Officially it was a Level 5 INES Scale event, but probably was actually a level 4 event. Reactor TMI-1 had it's license extended from April 2014 to until 2034. The plant has not seen any major atomic accidents since March 28, 1979.

Political fall-out[]

The U.S. 96th Congressional session passed U.S. legislation establishing a five-year nuclear safety, research, demonstration, and development program during the December of 1980.

Public opinion[]

The accident and initial establishment cover-up destroyed people's trust in atomic power. Many people though it was more a extreme incident than it was.

Medical opinion[]

The partial meltdown resulted in the release of unknown amounts of slightly radioactive gases and radioactive iodine into the environment and cancer reportedly went up a bit (one account said a total of 333 cases) for a few years.

Anti-nuclear people accused it causing cancer in a cancer free town and went in to a hysterical frenzy. The state denied there ever was any cancers at any time. The epidemiological studies analysing the rate of cancer in and around the area since the accident, determined there was a "small, statistically non-significant, increase" in the rate and so the came to the conclusion that no causal connection linking the accident with the slight gain in cancers can be made.

Official Investigations[]

[]

Effect on nuclear power industry[]

Litigation[]

A citizens's groups won $25 million in a 1981 out-of-court settlement in a class action suit against TMI. Part of this money was used to found the TMI Public Health Fund. A federal grand jury indicted Metropolitan Edison over the criminal falsification of safety test results prior to the accident. Met Ed also agreed to pay a $45,000 fine and to set up a $1 million account to help with emergency planning in the area surrounding the plant. The plant's operator and its insurers then paid at least $97 million in compensation after that.

A greater understanding atomic and industrial accident theories[]

The Seabrook plant, New Hampshire has not had any serious atomic accidents that I know of yet (2015).

The industrial safety expert Charles Perrow’ s Normal Accident Theory was inspired by the accident. The theory proposes that an accident occurs, resulting from an unanticipated interaction of multiple failures in a complex system. "Normal" accidents, or system accidents, are so-called by Mr Perrow because such accidents are inevitable in extremely complex systems.

Human error, technical failures, natural disasters, war, terrorism, organised crime, blunders, sabotage, complacent workers, corporate corruption and scientific ignorance can only be minimalised at best, so major accidents like this will occur, but only on an rather occasional basis.

The power station's\power plant's timeline,[]

| Date | Event |

|---|---|

| 1968–1970 | Construction |

| April 1974 | Reactor-1 online |

| Feb 1978 | Reactor-2 online |

| Mar. 1979 | TMI-2 accident occurred. Containment coolant and unknown amounts of radioactive contamination released into environment. |

| April 1979 | Containment steam vented to the atmosphere in order to stabilize the core. |

| July 1980 | TBq (43,000 curie s) of krypton were vented from the reactor building. |

| July 1980 | The first manned entry into the reactor building took place. |

| Nov. 1980 | An Advisory Panel for the Decontamination of TMI-2, composed of citizens, scientists, and State and local officials, held its first meeting in Harrisburg, PA. |

| Dec. 1980 | nuclear safety, research, demonstration, and development program. |

| July 1984 | The reactor vessel head (top) was removed. |

| Oct. 1985 | Defueling began. |

| July 1986 | The off-site shipment of reactor core debris began. |

| Aug. 1988 | GPU submitted a request for a proposal to amend the TMI-2 license to a "possession-only" license and to allow the facility to enter long-term monitoring storage. |

| Jan. 1990 | Defueling was completed. |

| July 1990 | GPU submitted its funding plan for placing $229 million in escrow for radiological decommissioning of the plant. |

| Jan. 1991 | The evaporation of accident-generated water began. |

| April 1991 | NRC published a notice of opportunity for a hearing on GPU's request for a license amendment. |

| Feb. 1992 | NRC issued a safety evaluation report and granted the license amendment. |

| Aug. 1993 | The processing of accident-generated water was completed involving 2.23 million gallons. |

| Sept. 1993 | NRC issued a possession-only license. |

| Sept. 1993 | The Advisory Panel for Decontamination of TMI-2 held its last meeting. |

| Dec. 1993 | Post-Defueling Monitoring Storage began. |

| Oct. 2009 | TMI-1 license extended from April 2014 until 2034. |

Videos[]

Three Mile Island Documentary Nuclear Power's Promise and Peril Retro Report The New York Times-0

The New York Times http://www.youtube.com/user/TheNewYorkTimes.

Meltdown at Three Mile Island.

Meltdown at Three Mile Island.

Modern Marvels S09E50 Inviting Disaster Three Mile Island.

Modern Marvels S09E50 Inviting Disaster Three Mile Island.

Also see[]

- Atomic accidents and disasters

- 1970s energy crises

- The Windscale reactor fire and 5 Sellafield incidents

- Chernobyl disaster

- Corporate malfeasance at the Peach Bottom Nuclear Generating Station

- Leningrad Nuclear Power Plant accidents

- Kyshtym (Urals Mountains) disaster

- Chalk River nuclear accident

- SL-1 Experimental Power Station accident

- A nuclear\atomic holocaust or nuclear apocalypse

Links[]

- http://www.wikiwand.com/en/Three_Mile_Island_accident

- http://www.world-nuclear.org/info/Safety-and-Security/Safety-of-Plants/Three-Mile-Island-accident/

- http://www.history.com/this-day-in-history/nuclear-accident-at-three-mile-island

- http://www.nrc.gov/reading-rm/doc-collections/fact-sheets/3mile-isle.html

- http://www.britannica.com/event/Three-Mile-Island-accident

- http://threemileisland.org/

- https://en.wikipedia.org/wiki/Three_Mile_Island_Nuclear_Generating_Station

- http://www.history.com/topics/three-mile-island

- http://www.world-nuclear.org/info/Safety-and-Security/Safety-of-Plants/Three-Mile-Island-accident/

- https://www.pennlive.com/news/2022/06/damaged-three-mile-island-reactor-gets-a-new-corporate-parent.html